Purifies impurities such as rust, dust, and oil in tank air and unpleasant odors, and supplies clean and safe air.

Tank air is not always clean

The air in the tank is not always clean. This is because when the tank is filled with air, the amount of water vapor saturated in the air decreases due to pressurization, and the water vapor that exceeds the saturated amount condenses and accumulates as water droplets in the tank.

The water droplets remaining inside this tank generate rust inside the tank over time, and they become sludge-like and accumulate in the tank.

It is possible that harmful substances such as rust, sludge, and lubricating oil for compressors are mixed in the air in the tank.

The photo on the right are not intentionally created or image-processed.

A cut diving tank that was normally used. Take a good look inside it.

※ Photo: Inside of the steal air tank registered in 1992.

However, most diving tanks are rented locally, and it is impossible to check the condition inside the tank and use a 100% clean tank. In other words, anyone can use a tank in this state and inhale air containing such harmful substances.

Electret filter with high dust removal performance

This "Clean Air System" has solved such problems.

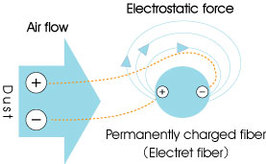

In a regulator equipped with a clean air system, the air in the tank is decompressed in the 1st stage and then passes through a state-of-the-art multilayer electret (permanent electrification) filter.

In this process, the filter adsorbs harmful substances and oil odors, creates clean and safe air, and supplies it to the diver.

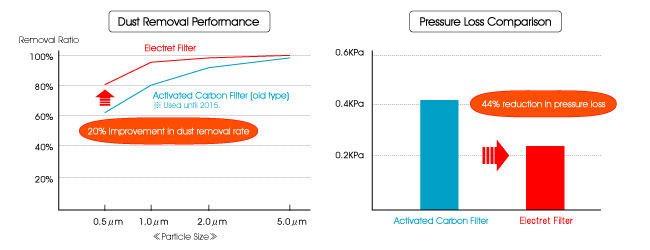

The filter material is determined through measurements and evaluations of dust collecting performance of fine particles from 0.5um to 5um.

The high dust collection rate is achieved by the effect that the PM2.5 (the harmful particles of 2.5μm or less of ) is, of course , also oil mist distributed in the 0.5 ~ 5μm, are electrically be attracted by the electrostatic force of the electret fiber.

Nowadays this electret filter is commonly used with medical filters, exclusive air cleaners and automobile premium air conditioners.

20% Improvement of collecting dust efficiency over the conventional cartridge, 44% reduction of the pressure drop.

※ Measurement condition: Count number of particles by the particle counter of each particle size of the air which is filtered by the filter cartridge installed in.

※ Measurement condition: Air flow 30L/min., At atmospheric pressure, the cartridge installed in the bio-filter.