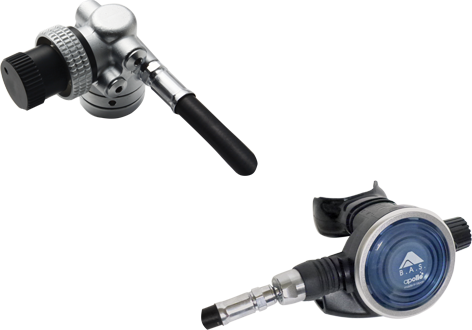

bio-regulator a-320 DIN Nrx

The package of the 1st stage regulator that lavishly uses tough forging body, and the easy-to-use 2nd stage regulator that equips swivel joint.

It supplies comfortable air even under all circumstances.

Features

1st stage

Reliably supply of comfortable air

Forged brass body

|

The body part adopt the basic member of forging. The highly durable and less variation forged parts are further processed with cutting work. |

※ The oxygen compatible Viton O-ring is employed in the high pressure region to support Nitrox as standard.

※ The 1st stage is EN250 CE certified, and it being used even with rebreather for pure oxygen application.

Double diaphragm system

|

The adoption of dual double diaphragm system relieves a worry of freezing moving parts under low-temperature environments. |

high-performance H.P. sheet

|

The heart of the 1st stage regulator is the newly developed tough and high-performance H.P. sheet bio 360. It stably supplies the air over the long duration which far surpass current conventional reference of "3 million times breath" and "about 3000 dive". ※ Tested with breathing machine by ourself. |  |

Cylindrical dust filter

|

It adopts a cylindrical dust filter. The dust filter in the high pressure region is high-density, thus susceptible to resistance. By adoption of the special mesh filter made of stainless, the flow restriction and pressure loss of this part has been minimized by the large filter area, two times larger than the traditional filter. |

2nd stage

Natural and comfortable breathing in the water

bio air system

|

"bio-air system", special structure inside of the 2nd stage, leads a direct air flow to the mouth. It will release the valve by sensing slight pressure change in order to achieve a comfortable breathing without any discomfort being affected by changes in depth or pressure remained in the tank. The mouthpiece-tube, relatively small in diameter, reduces the fatigue of the jaw in diving spanning a long period of time. |

Swivel joint L.P. hose

|

Well-established a swivel joint L.P. hose is equipped as standard, which reduces the fatigue of the jaw. |

Water-repellent plated containing

|

Main metal parts are water-repellent plated containing fluorine resin, which reduces the operation failure due to the deposition of salt. |

Specification

1st stage

- Material

Forged brass

- Finish

Satin chrome plated

- Type

Balanced diaphragm design, environmentally sealed

- H.P. ports

7/16" x2

- L.P. ports

3/8" x4

- Connections

DIN type

- Dust filter

Poppet type filter

- H.P. seat

bio-360

- Pressure level

Tank max 220bar, L.P. 9.6bar

- Weight

600g

2nd stage

- Material

ABS/PC body, TPU top cover

- Hose

70cm swiveling hose

- Weight

405g (with L.P. hose)

- Color

SV, BK

- Others

Breathing resistance adjust dial

B.A.S. bio air system

Water repellent plating metal parts

Technical information

(Important) Caution about parts and assembly adjustment used in overhaul

There are rare cases where the failure is caused as a result of using parts other than our standard service parts, or making incorrect assemble adjustment during overhaul. In such a case, it may interfere with durability and basic performance, and in the worst case it may cause unexpected phenomenons such as free flow during diving.

Each part is designed to be optimized in its shape and material for interfacing and assembling to other surrounding parts, and finalized through a long-term evaluation test. The diversion of similar other company parts may lead the danger above mentioned.

In addition, each component of the regulator has many important design factors such as tightening torque, adjustment dimension / adjustment position. When disassembling and assembling without adhering to these, unexpected events such as increased respiratory resistance under depth and loose screws or breakage due to excessive torque will occur.

In order to prevent the above events, please make sure that overhauls are either conducted at Nippon Sensuiki or a shop approved by Nippon Sensuiki.

Please note that we will not be responsible for accidents or malfunctions caused by using other manufacturer's parts or incorrect assembly adjustment.